Slightly Bigger Robots.

During a family trip to Japan last easter, I was fortunate enough to have a couple of hours to myself in the tech mecca of Tokyo, namely the Akihabara district.

My two hour “geek pilgrimage” involved plans for visiting four of the more iconic shops in Akihabara. These were Mak Japan, G-Front, Tsukomo Robot Kingdom and Vstone Robot Center.

After having spent quite some time looking at maps and web sites, I was finally able to locate the entrance of the MAK Japan shop. Turns out - they’re closed on wednesdays. Needless to say, this also included the wednesday we had chosen for our Akihabara visit.

Rather disappointed, I started looking around to see if I could find the G-Front shop instead. This was supposedly located in the immediate vicinity of MAK Japan and should be relatively easy to find. I looked around for any store signs. I checked Google maps. I asked japanese people that were hanging around outside the building that G-Front was supposedly in. I wasn’t able to find it. I gave up. (I later discovered that they had relocated to another building in Akihabara.)

Maybe this was just as well. If I had managed to locate these stores, I would probably have ended up spending all my money on a ridiculously expensive Cave PCB.

However,…

I did manage to locate both the Vstone Robot Center and Tsukomo Robot Kingdom. For a european maker geek like me, the experience was somewhat akin to Harry Potter’s experience stepping through to platform 9 3/4 before discovering the Hogwarth Express.

There were robots everywhere. Some were already familiar to me, but most of them were not. The shelves also contained every imaginable part that you would ever need for robot construction. This was maker heaven :)

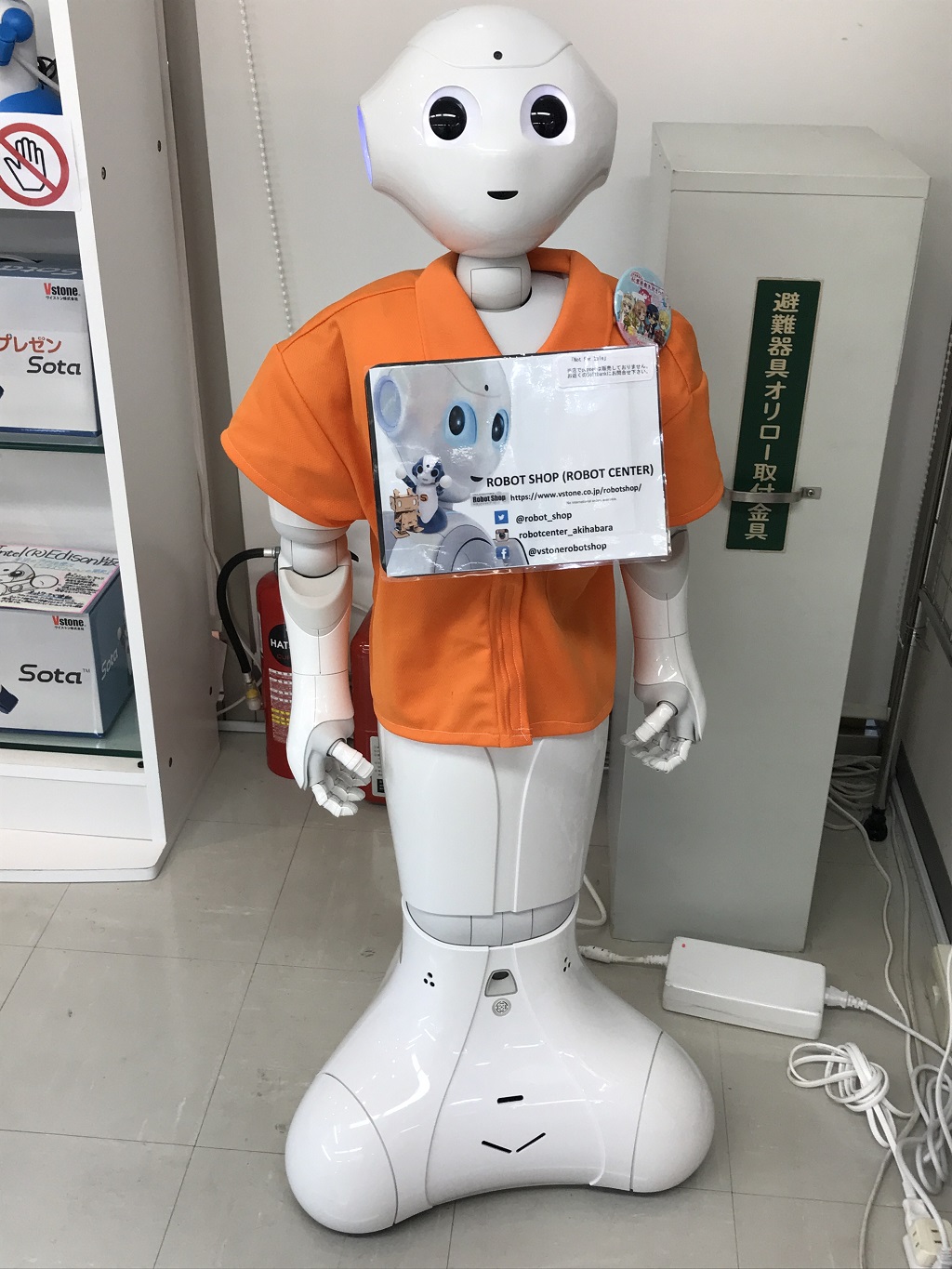

I almost had to suppress a laugh when I noticed a Pepper robot that was seemingly being used as a door stop in one of the shops. The company I work for had previously acquired the same robot for some unfathomable reason (we’re not a robotics company). If I were to hazard a guess, the acquisition had most likely been justified as being a state of the art AI showcase, intended for impressing customers and investors. I’m pretty sure that no one had popped the hood of this thing before spending the company’s cash, though. According to the specification, Pepper sports one Atom processor, 4 Gb of RAM and 16 Gb SD-card. The hardware cababilities of the “brains” of this thing is comparable to what can be expected from a Raspberry Pi.

Anyways,…

I had just entered robot heaven and proceeded to inspect the shelves and display cases. I had already decided on buying something. I just had to figure out what.

The rage in Japan seemed to be bipeds. From what I could tell from looking at shelves and local robot magazines, the most popular model seemed to be the KHR-3HV biped from the Japanese Manufacturer Kondo. Advertisements for these were to be found everywhere.

VStone was definetly the best stocked of the two shops. Sadly, VStone closed their shop in Akihabara just a couple of months after my visit. In addition to this Robocon Magazine decided to cease publication at almost the same time.

Further Inspiration⌗

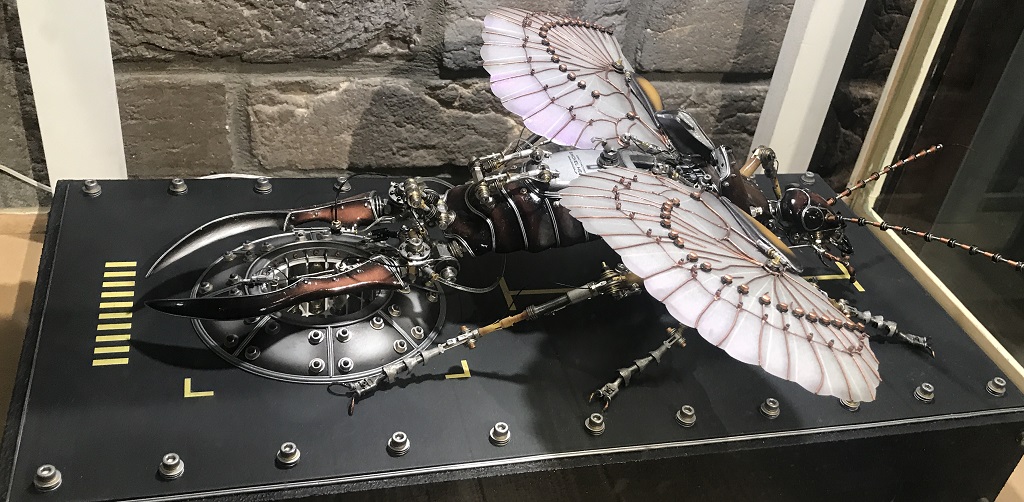

I am deeply fascinated by well made robotic creations. They don’t necessarily have to be functional robots. Robots can also be art. Just consider the works of Christopher Conte, Stephane Halleux, Mike Libby, Gregory Brotherton, James Corbett, Nemo Gould and Michihiro Matsuoka to name a few. There are also strange and beautiful goings on at craft factory Shovel Head

PS. Did I mention the 19.7 meter tall Unicorn Gundam statue in Tokyo ?

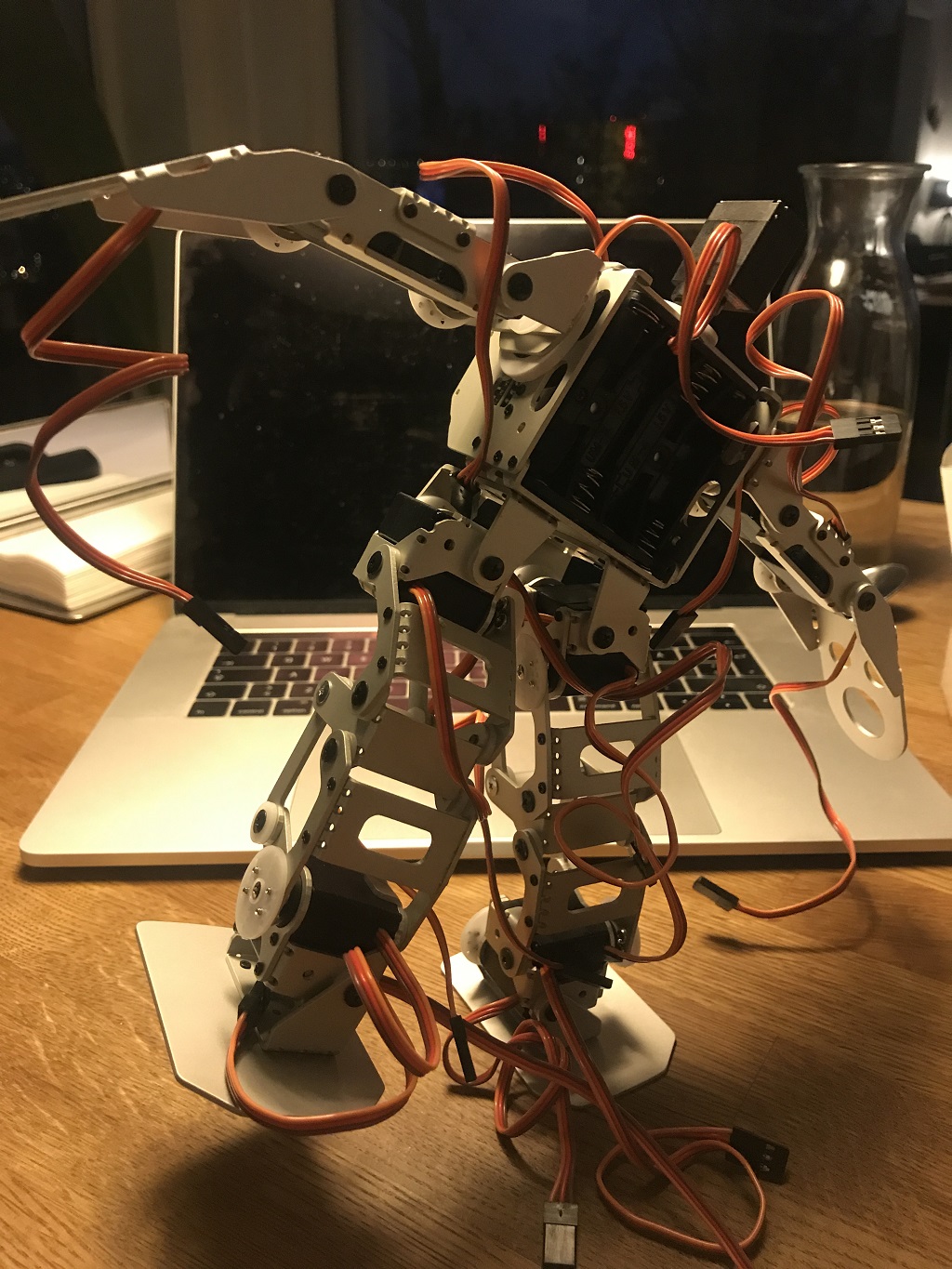

After returning home, I almost immediately started assembling the Robovie Nano kit. This has to be one of the cutest biped robots out there. The parts are incredibly well made, and I have to say that it was one of the more enjoyable builds that I have done. Too bad that I didn’t pick ut the remote control while I was there. I also had good fun playing around with the RobovieMaker motion editing software

Brimming with inspiration, I started to contemplate the idea of designing a serious robot of my own robot.

Before you can design anything, it is usually a good idea to consider which parts that are available and also consider the potential cost of the enterprise. Robotic projects can get really expensive - really fast. The biggest cost driver being the servos. You need a lot of them for even a basic robot.

The Robovie Nano is a good example of what is achievable whith traditional PWM controlled RC servos. It is a really nice little robot. Kudos to VStone for designing this little gem.

PWM RC servos are cheap, easily available and also easy to control, but they do have a few drawbacks.

- You cannot connect them in series. Depending on your robot configuration, this can lead to a wiring nightmare.

- These types of servos leave you no control over their torque and speed. Position is the only parameter.

- The servos are driven via a PWM signal and do not support two way communication. There is no protocol beyond voltage, frequency and duty cycle. This means that you cannot read back the servo position. This in turn makes it more difficult to create poses for use in a kinematics controller. With these types of servos you will have to drive each servo in turn, in order to achieve the desired pose (*). The alternative (with more advanced servos) is to unlock servo torque and just mechanically configure the pose before reading back the servo positions required to achieve a specific pose.

(*) This is with respect to the purpose of designing poses. When running the robot, your PWM controller will of course be able to drive all the servos in parallel.

Entering Unfamiliar Territory⌗

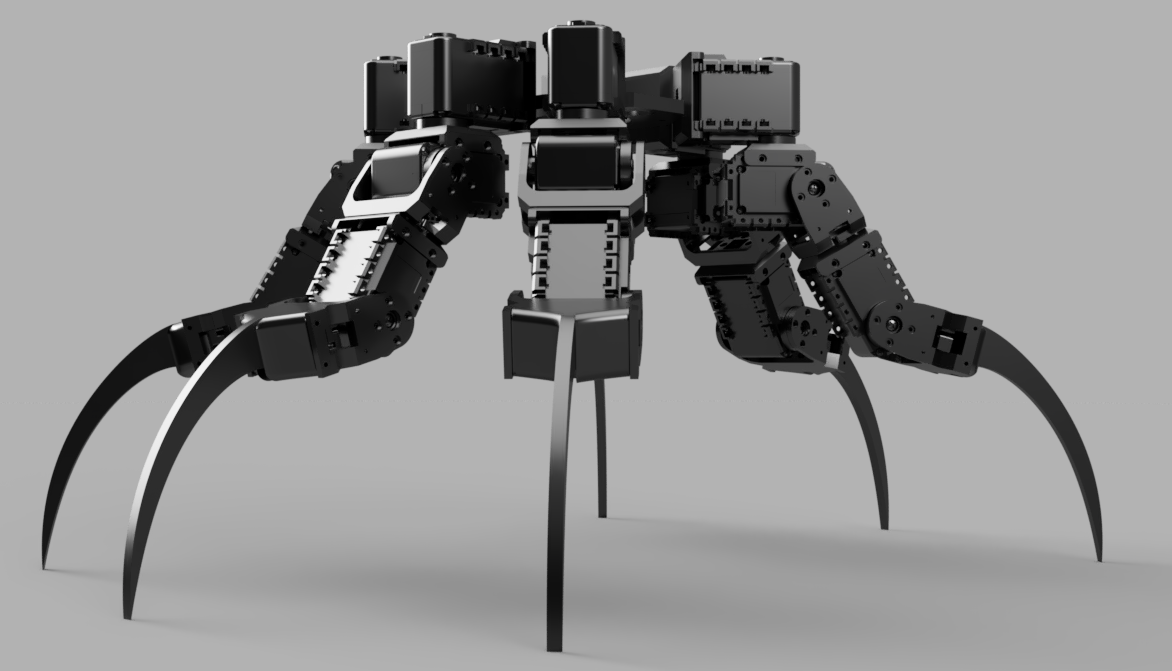

I researched several servo alternatives for my project (including servos made by Kondo and Herculex) and ended up ordering 18 Dynamixel MX-12W servos, along with a selecton of controllers from Trossen Robotics. You can check out the servo specification here.

I am going to build a biped at some point, but I thought it best to start out with something a bit simpler in order to familiarize myself with the Dynamixels.

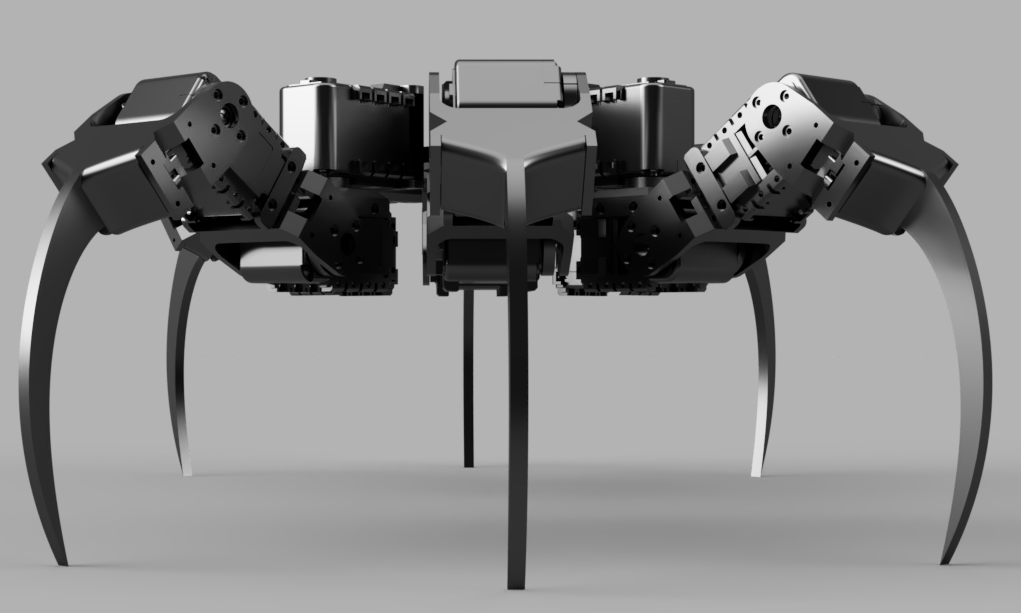

I am going to try them out in a hexapod configuration. One benefit of hexapods is that they are inherently stable. This allows me to concentrate on the easy stuff, like gait and kinematics. You can build bipeds without active balancing, but I guess that creating a semi-stable gait without the option of active balancing is going to be a real pain. (I don’t have an IMU fitted to the controller - yet.)

Initially, I’m planning on using the Arbotix-M controller together with an Arbotix Commander2.

Armed with my Prusa 3D printer, the Arbotix and the Dynamixels, I now believe have the necessary tools for constructing a robot. It remains to be seen if

- a) I have the necessary skills required for the build and

- b) if the MX-12W serovs have sufficient torque for handling some of the poses that are mechanically possible with my design.

I’m not worried, though. Problem “a” can be solved by throwing books at the problem and problem “b” can be solved by throwing money at the problem. Expect things to change. That’s what iterations are for.

It is also tempting to design a dynamixel controller of my own at some point. There are beefier MCUs out there than the ATmega644 that resides on the Arbotix-M. WiFi/Bluetooth capability and an oboard IMU wouldn’t hurt either.

And - Yeah. It’s got 18 72MHz ARM cortex M3 processors - not counting the brains :D

Random Inspirational Art, Automata and Robot Reading Materials⌗

- “Mechanical Mutants”, craft factory Shovel Head

- “Robo sapiens”, Peter Menzel, Faith D’Alusio, 2000

- “Moveable Illustration”, Aquido Nishida

- “Gear Heads - The Turbulent Rise of Robotic Sports”, Brad Stone, 2003

- “Robocon Magazine” (Unfortunately no longer in print. You may be able to find back issues at your local robot store.)

- Device gallery exhibition catalogs (Device I - III)

- How House Robot Exhibition catalogs

- “Junkbots, Bugbots & Bots on Wheels”, Dave Hrynkiw, Mark W. Tilden, 2002